Drive 28BYJ-48 Stepper Motor with ULN2003 driver activating 2 coils and the BeagleBone Black

In this post, I show how to drive the stepper motor 28BYJ-48 in full step mode activating 2 coils with the driver ULN2003. In this entry, you can find more about this stepper motor, this driver and how to use it in a Full Step activation mode with 1 coil.

Remember that the 28BYJ-48 is a stepper motor that moves of steps or “degree intervals”. It has an internal gear set that let it to turn 2048 steps in each revolution in a mode that is called Full Step or 4096 steps in each revolution in a mode called Half Step.

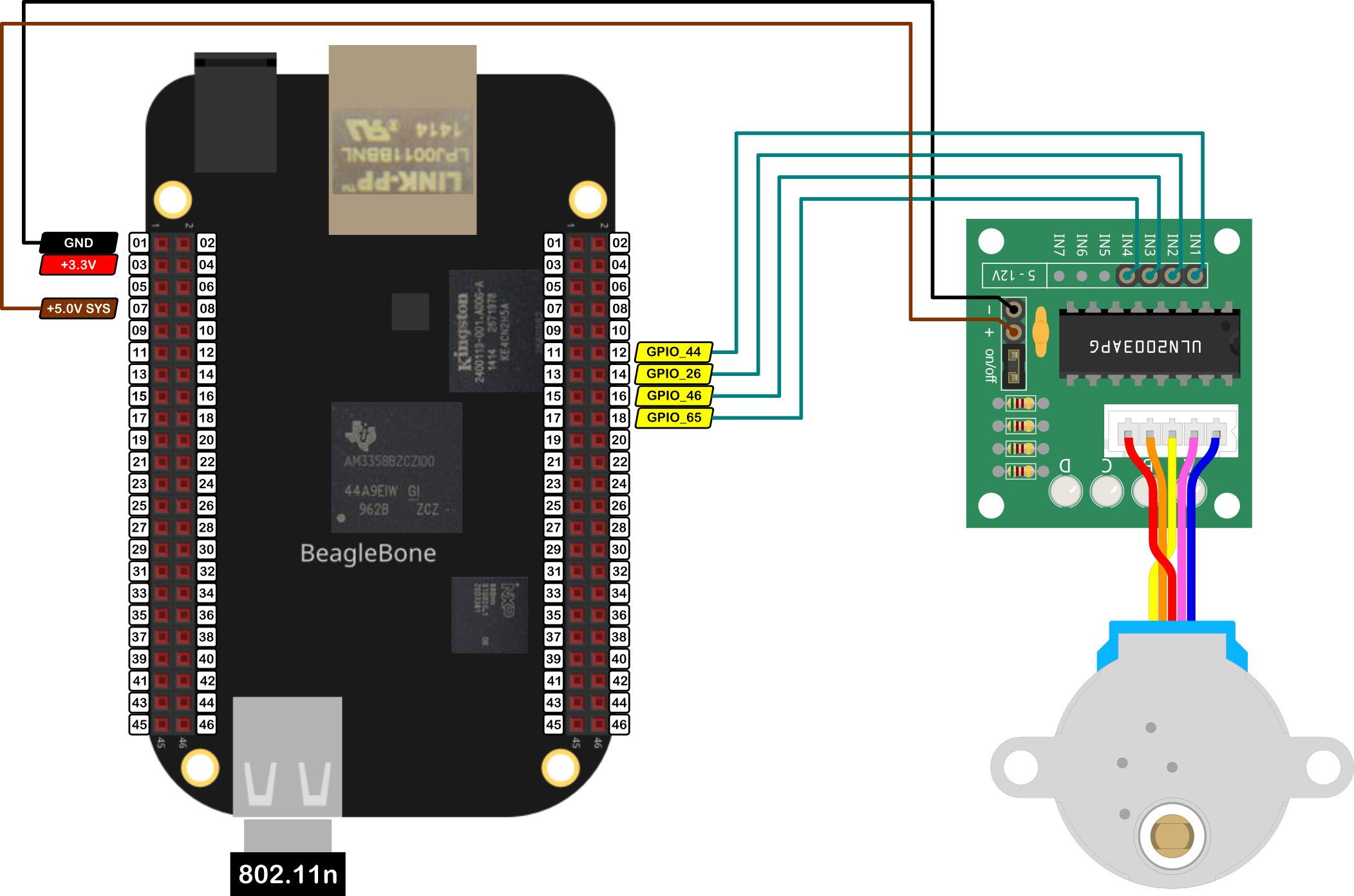

It is important to remember that the logic voltage for the BeagleBone is 3.3V. If the user provides a greater voltage, the BeagleBone could be damaged.

Circuit and components

The circuit can be seen in Figure 1. It consists of a L298N driver module , a low voltage DC Motor, batteries, and the BeagleBone.

The components are:

- 1 28BYJ-48 stepper motor 5V

- 1 ULN2003 module driver

- 1 Protoboard mini

- Jumpers male-male to make the connections

The pins used for control the stepper motor are:

- GPIO P8_12, P8_14, P8_16 and P8_18 to control the motor rotation speed and direction

Coding

First, four GPIO objects are declared and named as IN1, IN2, IN3 and IN4. These pines will be used to declare and initialize a StepperMotor object after in the code.

1

2

3

4

5

6

7

8

9

10

11

12

13

// Declaring the pins for motor

GPIO IN1 (P8_12);

GPIO IN2 (P8_14);

GPIO IN3 (P8_16);

GPIO IN4 (P8_18);

/*

Declare the 28BYJ-48 stepper motor object with default parameters:

full step with the activation of 1 coil,

default 2048 steps per revolution

and a default maximum speed of 500 steps/second

*/

StepperMotor myStepper (IN1, IN2, IN3, IN4);

The StepperMotor object constructor definition is shown in the next listing. It takes seven input parameters with the last three of them with default values. The first four parameters are the GPIO pins to control the stepper motors. The last three have default values if the user does not set up the next:

- The control mode for the stepper motor, i.e., if the stepper motor will be controlled with one of the next three modes:

- Full step with one coil activation.

- Full step with two coil activation.

- Half step with two coil activation by nature.

- Other way, by example using another custom driver.

- The steps per revolution of the motor, 2048 steps as default value.

- The maximum rotation speed of the motor, 500 steps per revolution as a default value.

1

2

3

4

5

6

7

// Overload constructor

StepperMotor(

GPIO, GPIO, GPIO, GPIO,

STEPPER_MODE controlMode = fullStep1Coil,

unsigned int stepsPerRevolution = 2048,

unsigned int maxSpeed = 500

);

The StepperMotor object constructor declaration is shown in the next listing. It requirers at least, the four GPIO pins to control the stepper motor an initialize them as OUTPUT pins with the private method InitMotorPins(). Then, the correct number of activation sequence steps is set up in the variable stepsPerMode according to the control mode that the user wants, 4 steps for Full Step mode with 1 or 2 coils activation and 8 steps for Half Step mode.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

// Overload Constructor

StepperMotor::StepperMotor (GPIO newMotorPin1,

GPIO newMotorPin2,

GPIO newMotorPin3,

GPIO newMotorPin4,

STEPPER_MODE newControlMode,

unsigned int newStepsPerRevolution,

unsigned int newMaxSpeed) :

motorPin1 (newMotorPin1),

motorPin2 (newMotorPin2),

motorPin3 (newMotorPin3),

motorPin4 (newMotorPin4),

controlMode (newControlMode),

stepsPerRevolution (newStepsPerRevolution),

maxSpeed (newMaxSpeed)

{

InitMotorPins();

stepsCounter = 0;

currentStep = 0;

std::string modeString;

switch (controlMode)

{

case fullStep1Coil:

modeString = "Full step with 1 Coil";

stepsPerMode = fullStep1CoilVector.size();

break;

case halfStep:

modeString = "Half step";

stepsPerMode = halfStepVector.size();

break;

case fullStep2Coils:

modeString = "Full step with 2 coils";

stepsPerMode = fullStep2CoilsVector.size();

break;

case driver:

modeString = "Driver mode was chosen";

break;

}

std::string message;

message = "\nStepperMotor object with the next parameters / pins was created:\n" +

std::string("\tMotorPin1: ") + this->motorPin1.GetPinHeaderId() +

"\n" +

std::string("\tMotorPin2: ") + this->motorPin2.GetPinHeaderId() +

"\n" +

std::string("\tMotorPin3: ") + this->motorPin3.GetPinHeaderId() +

"\n" +

std::string("\tMotorPin4: ") + this->motorPin4.GetPinHeaderId() +

"\n" +

std::string("\tControl Mode: ") + modeString + "\n" +

std::string("\tMax speed: ") + std::to_string(maxSpeed) + "\n\n";

std::cout << RainbowText(message, "Light Gray");

}

/*

Private method to initialize the Pins

*/

void StepperMotor::InitMotorPins()

{

// Set the right modes for the pins

motorPin1.SetMode(OUTPUT);

motorPin2.SetMode(OUTPUT);

motorPin3.SetMode(OUTPUT);

motorPin4.SetMode(OUTPUT);

}

This DCMotor object is used to initialize the L298N object. This inheritance structure has the goal to encapsulate the corresponding methods for any generic DC motor avoiding repeat code in the L298N object and focusing on the methods to drive / brake the DC motor, and not only one, but the two motors at the same time and in a different direction if it desired.

1

2

// Declare the L298N Module

L298N myL298NModule (MotorLeft);

The L298N object constructor is shown in the next listing:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

// Overload constructor from DCMotor object for ONLY the MotorA

L298N::L298N (DCMotor& newMotorA) :

MotorA (newMotorA)

{

// Set the flags about which motors are used

motorAisUsed = true;

motorBisUsed = false;

std::string message;

std::string swapStringMotorA {this->MotorA.swapSpinFlag ? "True" : "False"};

message = "\nTB6612FNG driver module with the next components / pins was created and activated:\n" +

std::string("\tMotorA:\n") +

std::string("\t\tAIN1: ") + this->MotorA.input1Pin.GetPinHeaderId() + "\n" +

std::string("\t\tAIN2: ") + this->MotorA.input2Pin.GetPinHeaderId() + "\n" +

std::string("\t\tPWMA: ") + this->MotorA.pwmPin.GetPinHeaderId() + "\n" +

std::string("\t\tSwap Spin: ") + swapStringMotorA + "\n" +

"\n\n";

std::cout << RainbowText(message, "Light Red");

}

To make turn the DC motor, the method is L298N::DCMotor::Drive can be used. This receives two parameters:

- Speed in percentage, i.e. integer values between 100 and -100

- Time of the spin duration in milliseconds

A positive speed value sets the motor to turn in the CW direction, while, a negative speed value sets the motor to turn in the CCW direction.

1

myL298NModule.MotorA.Drive(speed,duration);

A positive speed value sets the motor to turn in the CW direction, while, a negative speed value sets the motor to turn in the CCW direction.

1

2

3

4

5

6

7

8

9

10

11

// Turn the motor in CW direction

for (int speed = 0; speed < 100; speed += 10)

myL298NModule.MotorA.Drive(speed,1000);

for (int speed = 100; speed > 0; speed -= 10)

myL298NModule.MotorA.Drive(speed,1000);

// Turn the motor in CCW direction

for (int speed = 0; speed > -100; speed -= 10)

myL298NModule.MotorA.Drive(speed,1000);

for (int speed = -100; speed < 0; speed += 10)

myL298NModule.MotorA.Drive(speed,1000);

The complete code for this application is shown in the next listing together with its corresponding execution output.

28BYJ-48-ULN2003_1.1.cpp

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

/******************************************************************************

28BYJ48-ULN2003_1.2.cpp

@wgaonar

08/04/2022

https://github.com/wgaonar/BeagleCPP

- Move the stepperMotor by steps in fullStep with 2 Coils mode

Class: STEPPERMOTOR

******************************************************************************/

#include <iostream>

#include "../../../Sources/STEPPERMOTOR.h"

using namespace std;

// Declaring the pins for motor

GPIO IN1 (P8_12);

GPIO IN2 (P8_14);

GPIO IN3 (P8_16);

GPIO IN4 (P8_18);

/*

Declare the stepper motor mode

(fullStep1Coil / fullStep2Coils / halfStep)

*/

STEPPER_MODE controlMode {fullStep2Coils};

// Declare the number of steps per revolution

unsigned int stepsPerRevolution {2048};

// Declare the maxSpeed steps/second

unsigned int maxSpeed = 500;

/*

Declare the 28BYJ-48 stepper motor object with:

full step with 2 coils at the same time,

2048 steps per revolution

and a maximum speed of 500 steps/second

*/

StepperMotor myStepper (IN1, IN2, IN3, IN4,

controlMode, stepsPerRevolution,

maxSpeed);

int main()

{

string message = "Main program starting here...";

cout << RainbowText(message,"Blue", "White", "Bold") << endl;

/*

Turn the stepper motor 1/4-turn in CW direction in fullstep

mode with 2 coils at the same time at 500 steps/second

*/

myStepper.TurnBySteps(CW, 512);

cout << "Steps executed by the motor: " << myStepper.GetStepsCounter() << endl;

cout << "Actual position of the motor axis: " << myStepper.GetCurrentStep() << endl;

/*

Turn the stepper motor 1/4-turn in CCW direction in fullstep

mode with 2 coils at the same time at 500 steps/second

*/

myStepper.TurnBySteps(CCW, 512);

cout << "Steps executed by the motor: " << myStepper.GetStepsCounter() << endl;

cout << "Actual position of the motor axis: " << myStepper.GetCurrentStep() << endl;

message = "Main program finishes here...";

cout << RainbowText(message,"Blue", "White","Bold") << endl;

return 0;

}

Se you in the next post.